+86 15633683072

When manufacturers invest in welding automation, the real challenge is not choosing a robot—it is turning that robot into a stable, repeatable production tool. This is exactly where robotics integrators create value. In welding applications, success depends far more on robot system integration than on hardware specifications.

This article approaches welding automation from a different angle: how integration capability determines whether a project becomes a long-term asset or an ongoing headache.

Many welding projects fail quietly. The robot runs, the weld looks acceptable on day one, but weeks later quality drifts, cycle time slips, and manual rework returns.

The root cause is often weak robot system integration.

Welding involves interaction between:

robot motion

welding power source behavior

fixtures and part repeatability

thermal distortion

production rhythm

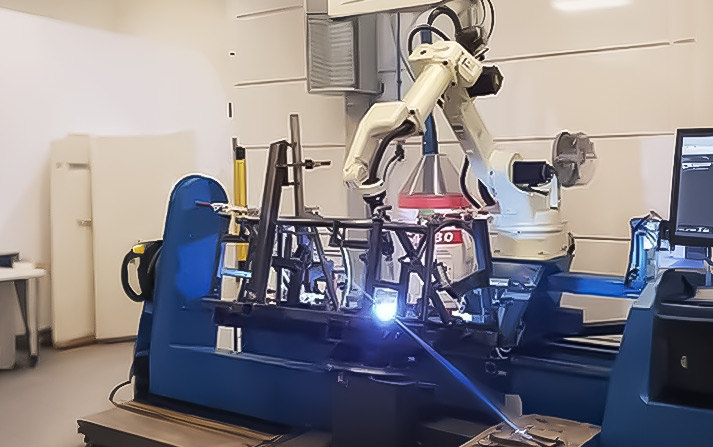

Professional robotics integrators treat welding automation as a closed-loop system, not a collection of components. This system mindset is what separates a true robotic system integrator from a machine builder.

Welding automation looks simple on paper: pick, position, weld. In practice, variation is unavoidable. Parts move, joints change, materials react differently to heat.

This is why welding projects rely heavily on custom robot system integration. Experienced robotics integrators design systems that:

tolerate part inconsistency

control heat input precisely

synchronize robots with positioners

maintain weld quality over long production runs

Without this depth of robot system integration, even advanced robots struggle to deliver consistent results.

A common mistake is chasing faster robot motion. Skilled robotics integrators focus instead on flow.

Through custom robot system integration, they optimize:

weld sequencing to minimize distortion

station balance to avoid robot waiting time

fixture ergonomics for faster loading

software logic for stable takt time

This approach improves throughput without sacrificing weld integrity. A capable robotic system integrator understands that productivity comes from coordination, not raw speed.

Standard welding cells work well for simple, high-volume parts. Problems appear when products evolve.

At that point, manufacturers discover the limits of fixed designs. In contrast, systems built through custom robot system integration are adaptable. Experienced robotics integrators design for:

future part variants

process upgrades

additional robots or stations

This flexibility is a direct result of strong robot system integration architecture, not luck.

A robotic system integrator acts as a technical translator—connecting production goals with automation reality.

Their role includes:

translating weld quality requirements into control logic

aligning mechanical design with software strategy

ensuring safety systems do not disrupt productivity

This coordination is why manufacturers increasingly choose specialized robotics integrators rather than building welding automation internally.

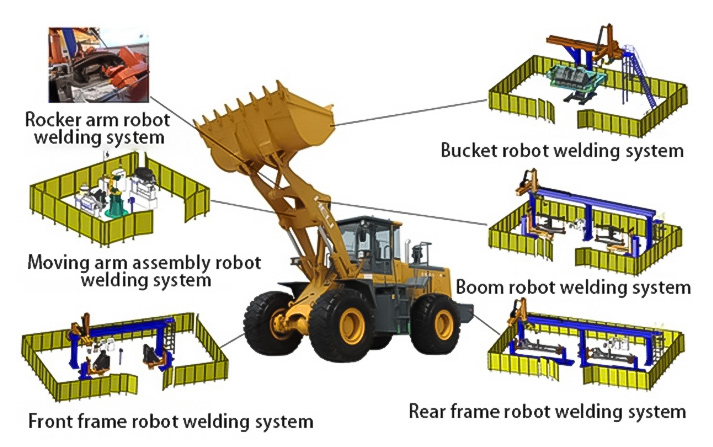

One advantage of working with experienced robotics integrators is cross-industry knowledge. Welding challenges in construction machinery, automotive structures, or industrial equipment often share common patterns.

A seasoned robotic system integrator applies lessons learned across industries to refine:

seam tracking strategies

fixture repeatability concepts

thermal management approaches

This accumulated integration knowledge is difficult to replicate in-house.

When comparing robotics integrators, marketing materials rarely tell the full story. Practical evaluation should focus on:

depth of robot system integration experience

ability to deliver custom robot system integration

real commissioning and debugging capability

on-site engineering support

A reliable robotic system integrator should be comfortable discussing failure modes—not just success stories.

Founded in 1994, we have focused exclusively on robotic welding and assembly automation for manufacturing enterprises worldwide. As one of the experienced robotics integrators in this field, we deliver complete welding workstations and production lines based on real production constraints.

Our strength lies in custom robot system integration—from process validation and fixture design to control logic and on-site commissioning. Our engineers work directly at customer facilities to ensure systems run stably under real operating conditions, not just during factory acceptance tests.

If you are selecting a robotic system integrator for welding applications, look beyond robots and brands. The real differentiator is integration depth—and that is where experienced robotics integrators make the difference between automation that works and automation that lasts.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com